Lab Experiments

The Chair of Industrial Chemistry offers various experiments for compulsory and advanced practical courses within the framework of the courses of study in bioengineering, chemical engineering and chemistry.

In-depth Lab

Students interested in an in-depth lab will be involved in the current research of the department. Current proposed topics can be found here. Since the topics for student work can change very quickly, it is also recommended to ask the assistants directly.

Compulsory Lab Experiments

The following experiments are offered by the chair TC

| Lab | Experiment | Title | Room |

| CIW/CCB | TC 18 | Telomerization of Myrcens with amines. | PT U09 |

| CIW | TC 19 | Introduction to analytics by means of NMR using the example of transfer hydrogenation | PT U09 |

| CIW3/CCB | RT 02 | Chemical reactors: stirred tank reactors (discontinuous & continuous) | PT U 09 |

| CIW3/CCB | RT 03 | Chemical reactors: Tube Reactor (TC11&TC14 are to be carried out one after the other). | PT U 09 |

RT 02: Chemical reactors: stirred tank reactors

A prerequisite for the manufacture of a chemical product is first of all a chemical reaction of the starting materials in a chemical reactor. In order to be able to design and operate this reactor optimally, knowledge of the behavior of chemical reactors is indispensable. Almost every chemical reactor can be traced back to the basic types (or combinations thereof) presented in the practical experiments TC11 and TC 14. The aim of the practical course is to introduce the behavior of the basic types of chemical reactors on the basis of a model reaction for a stirred tank reactor, which is operated discontinuously and continuously.

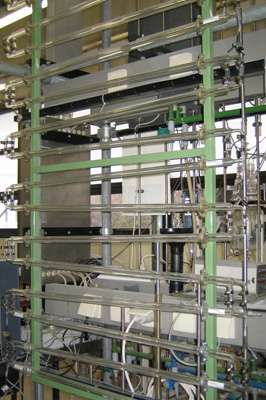

RT 03: Chemical reactors: flow tube

A prerequisite for the manufacture of a chemical product is first of all a chemical reaction of the starting materials in a chemical reactor. In order to be able to design and operate this reactor optimally, knowledge of the behavior of chemical reactors is indispensable. Almost every chemical reactor can be traced back to the basic types (or combinations thereof) presented in these practical experiments. The aim of the practical experiment is an introduction to the behavior of the basic types of chemical reactors using a model reaction for a tubular reactor.