Miniplant

CSTR + Mixer settler + Distillation

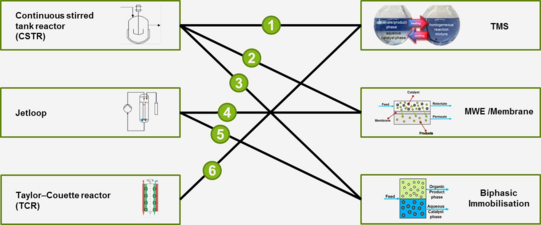

Continuous stirred tank reactors (CSTR) facilitate rapid dilution of reagents through mixing. As opposed to PFRs, the performance of CSTRs is less susceptible to changes in the influent composition, which makes it ideal for a variety of industrial applications.

Mixer settlers are a class of mineral process equipment used in the solvent extraction process. A mixer settler consists of a first stage that mixes the phases together followed by a quiescent settling stage that allows the phases to separate by gravity.

Components are seperated from a liquid mixture by using selective boiling and condensation (Distillation).

CSTR + Membrane filtration

Continuous stirred tank reactors (CSTR) facilitate rapid dilution of reagents through mixing. As opposed to PFRs, the performance of CSTRs is less susceptible to changes in the influent composition, which makes it ideal for a variety of industrial applications.

Membrane filtration is a method of separating particles in liquid solutions or gas mixtures. The semi-permeable membrane acts as a barrier which retains larger particles, while allowing smaller molecules to pass through the membrane into the permeate.

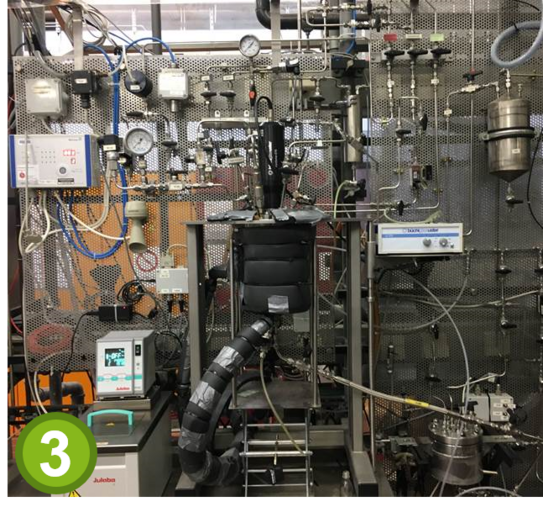

CSTR + Ex situ extraction with decanter

Continuous stirred tank reactors (CSTR) facilitate rapid dilution of reagents through mixing. As opposed to PFRs, the performance of CSTRs is less susceptible to changes in the influent composition, which makes it ideal for a variety of industrial applications.

Extraction is any separation process in which one or more components are dissolved out of a mixture of substances with the aid of an extraction agent. Extraction is used when distillation or rectification are not an option or the extraction process is more cost-effective.

CSTR + Catalyst immobilization with decanter

Continuous stirred tank reactors (CSTR) facilitate rapid dilution of reagents through mixing. As opposed to PFRs, the performance of CSTRs is less susceptible to changes in the influent composition, which makes it ideal for a variety of industrial applications.

The benefits of using immobilized catalysts in industrial processes include potential for decreased metal contamination in products and waste streams and the ability to easily recover and reuse the catalysts, both of which can decrease the cost of a synthesis.

Jetloop + Membrane reactor

Membrane reactors have evident advantages over conventional biological or chemical processes. These advantages are lower footprint, easiness of automation and operation, handling with higher organic loadings.

Jet loop reactors (JLRs) have many advantages over classical reactors such as, simple construction, lower construction and operation costs, more circulation under the same energy input, no moving part in the reactor, easy transferfrom pilot scale to industrial scale.

Jetloop + Biphasic Immobilization

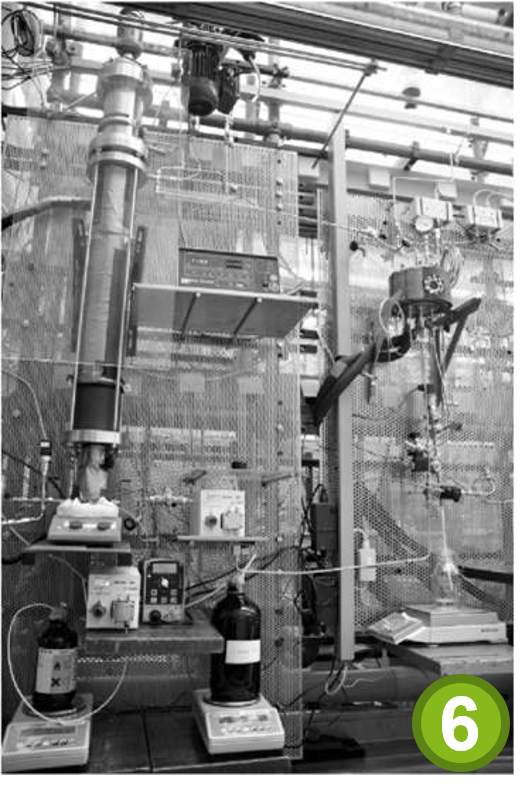

TMS in a Taylor–Couette reactor (TCR)

The Taylor-Couette reactor (TCR) is an apparatus that capitalizes on the Taylor-Couette flow, which allows many flow regimes and conditions to perform (bio-)chemical conversions with precise control of various reactor characteristics.

Thermomorphic Multiphase Systems (TMS) ensure a homogeneous reaction in a monophasic reaction mixture at reaction temperature and the recovery of the homogeneous transition-metal catalyst through liquid–liquid separation at a lower separation temperature.