M. Sc. Alexander Kühl

Curriculum Vitae

In October 2013, Alexander Kühl started studying Chemical Engineering at the Technische Universität Dortmund. In 2018, he finished his bachelor thesis with the topic “Investigation of the hydroaminomethylation of 1-Decene and determination of the influence of significant reaction parameters” at the laboratory of industrial chemistry. He continued his master studies at the TU Dortmund and successfully completed his master in 2021. His master thesis with the title “Reconstruction and Commissioning of a continuous miniplant for the application of thermomorphic multiphase systems in homogenous catalysis” was written at the laboratory of industrial chemistry. Following his master studies, he started his doctoral studies in March 2021.

Research Topic

With decreasing numbers of oil deposits, renewable resources gain increasing significance in the chemical industry. Chemicals extracted from renewable resources are often times highly functionalized molecules with unsaturated carbon chains, which are used in surfactants or as active ingredients in pharmaceuticals. A limiting factor for their usage is the reduced water solubility due to long carbon chains.

The Ethenolysis, a reaction in which unsaturated carbon chains react with ethylene in a metathesis reaction, is one way to reduce the length of these carbon chains.

For increased selectivity and mild reaction conditions, homogeneous catalysts are deployed in this reaction. The downside of homogeneous catalysis is that the catalyst together with the substrates and products are solved in a single phase. Hence, the recovery of the catalyst is increasingly difficult in comparison to heterogeneous catalysis.

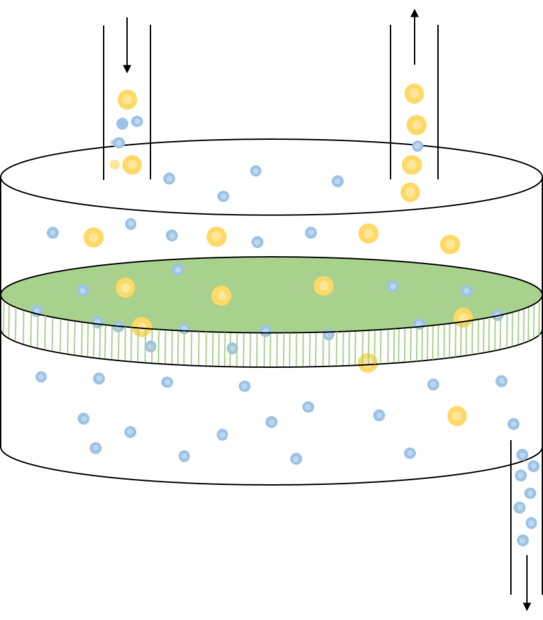

Membrane technology is one way to recover solved catalysts without complicated downstream applications or major energy consumption. The usually larger catalyst molecules don’t permeate through the membrane. Furthermore, membranes enable the separation of the product from the reaction mixture. These versatile applications enable different membrane concepts.

Publications

- Roth, T. F. H., Kühl, A., Spiekermann, M. L., Wegener, H. W., Seidensticker,T. (2024) "Biodiesel as a Sustainable Platform Chemical Enabled by Selective Partial Hydrogenation: Compounds Outplace Combustion?!",ChemSusChem, e202400036 DOI: 10.1002/cssc.202400036.

- Gottu Mukkul, A. R., Riemer, T. B., Kühl, A., Vogt, D., Engell, S., (2024) "Iterative real-time optimization of a reductive amination process in a thermomorphic multiphase system" Chem. Eng. Sci., 287(119662), DOI: 10.1016/j.ces.2023.119662.

- May 2022, Dortmund, Germany, 11th Workshop on Fats and Oils as Renewable Feedstock for the Chemical Industry, “Recycling of an Unmodified Grubbs-Hoveyda Catalyst in the Self Metathesis of Cardanol via Organic Solvent Nanofiltration”

- June 2022, Weimar, Germany, 55. Jahrestreffen Deutscher Katalytiker, „Recycling of an Unmodified Grubbs-Hoveyda Catalyst in the Self Metathesis of Cardanol via Organic Solvent Nanofiltration”