Dr. rer. nat. Andreas Vorholt

Curriculum Vitae

| Diploma (Chemistry) | 2003 – 2008 TU Dortmund |

| Semester abroad | 2007 University of Queensland, Brisbane, Australia |

| Master of Science | 2009 – 2011 Economic Sciences, TU Dortmund |

| PhD (Dr. rer. nat.) | 2008 – 2011 Industrial Chemistry (summa cum laude), TU Dortmund |

| Consultant | since 2012 Introduction of LEAN management in medium-sized production companies |

| Assistant Professor (Habilitation) | 2012 – 2017 Institute for Technische Chemie, TU Dortmund; Manager of a new independent research group for Resource Efficient Chemistry |

| Research stay | 01/2015 – 04/2015 With Dr. M. V. Garland at A*Star Institute for Chemical and engineering sciences, Singapore |

| Lectureship | since 2016 Institute for Industrial Chemistry & Petrochemistry, RWTH Aachen: multiphasic catalysis and immobilisation |

| Lectureship | since 2018 Institute for Industrial Chemistry, TU Dortmund: value added in chemical industry & chemical processes in case studies |

| Group leader | since 2018 'Multiphasen Katalyse', MPI CEC |

Lectures

Wertschöpfung in der chemischen Industrie (SS 2021 1VV 2VÜ 3C)

Strategic planning and operational management techniques are integral to the professional lives of engineers and scientists. In this immersion, fundamentals are laid and practiced on case studies in mixed groups.

Chemische Prozesse in Fallstudien (WS 2021/22 2PV 1PÜ 4C)

Students work on case studies based on real projects. Students are trained to independently gather information, make decisions and analyze the results in comparison with other solutions.

Research Topic

The transition from an economy based on fossil resources to one based on renewable energy and raw materials has many challenges, including the chemical conversion of resources to energy storage and materials.

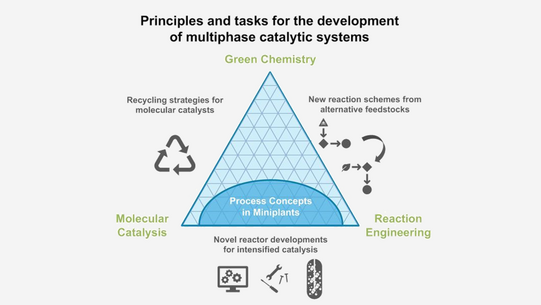

In the Multiphase Catalysis group we aim to approach catalysis research using a multiscale approach to gain a deeper understanding of the underlying phenomenology. Starting from the molecular level to the phase behavior to the process level, transformations are considered to make them more sustainable and efficient.

This field lies at the interface between catalysis, chemical reaction engineering and process intensification. For this reason, this group combines the forces of chemistry and chemical process engineering to work on a number of areas including:

- Exploration of new reaction schemes for obtaining substitute products to existing commodities (e.g., fuels) from alternative resources.

- Investigation of different recycling strategies for molecular catalysts in multiphase systems, in combination with predictive models.

- Develop novel reactor concepts for enhanced catalysis to improve mass transfer and catalyst recyclability.

The overall goal is to bring together the knowledge gained to implement miniplant-scale process concepts and to use operando analytics to monitor the long-term stability of catalysts.

Support