Reaction Equipment

Autoclaves

Autoclaves:

- Different sizes of stainless steel autoclaves à 25 mL to 5000 mL, leakproof up to 150 bar

- Different Sizes of Glass autoclaves à 20 mL to 200 mL, leakproof up to 10 bar

- Special reactor concepts: Glass window reactor, Jet-Loop Reactor, Taylor Couette Reactor, ATR-probe reactor, IR-glass window reactor

We use it for:

- Pressure Experiments

- Getting insight in the phase behaviour of biphasic mixtures

- Investigating influence of reactor concept on the reaction performance in biphasic mixtures

- Investigating the reaction in situ by ATR measurements

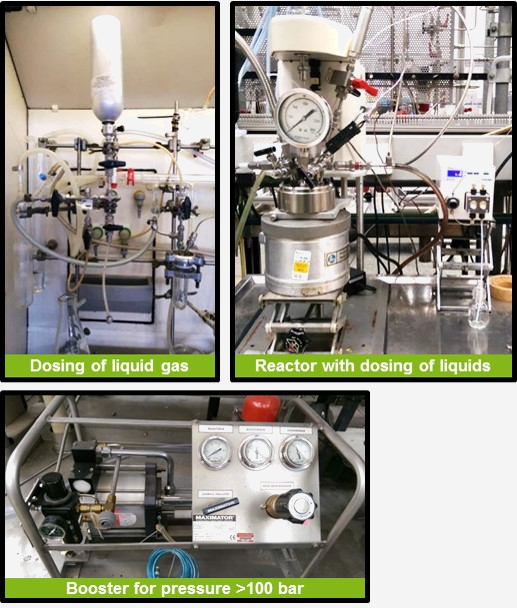

Dosing and Sampling

Dosing:

- Gases (hydrogen, carbon monoxide, syngas, argon, nitrogen)

- Liquid gases (ammonia, butadiene, isobutene)

- Liquids (continuos dosing over HPLC-pump)

Sampling:

- Gases → gas uptake measurements over mass flow indicators

- Liquids → automatic sampling system

- Online GC → automated measurements of the reaction system

We use it for:

- Investigations in the reaction performance of liquid gases

- Kinetic measurements

- Monitoring of continous experiments in miniplant scale

Purification and Recovery

Purification methods:

- Distillable compounds à Kugelrohr- / Spaltrohrdistillation, large distillation column

- Column chromatography

- Preparative HPLC column

Recovery methods:

- Monophasic systems à crystallization, membranes

- Biphasic systems à decanter, extractors (e.g. rotating disc contactor)

- Online GC à automated measurements of the reaction system

We use it for:

- Purification of value products

- Recovery of precious transition metal catalysts